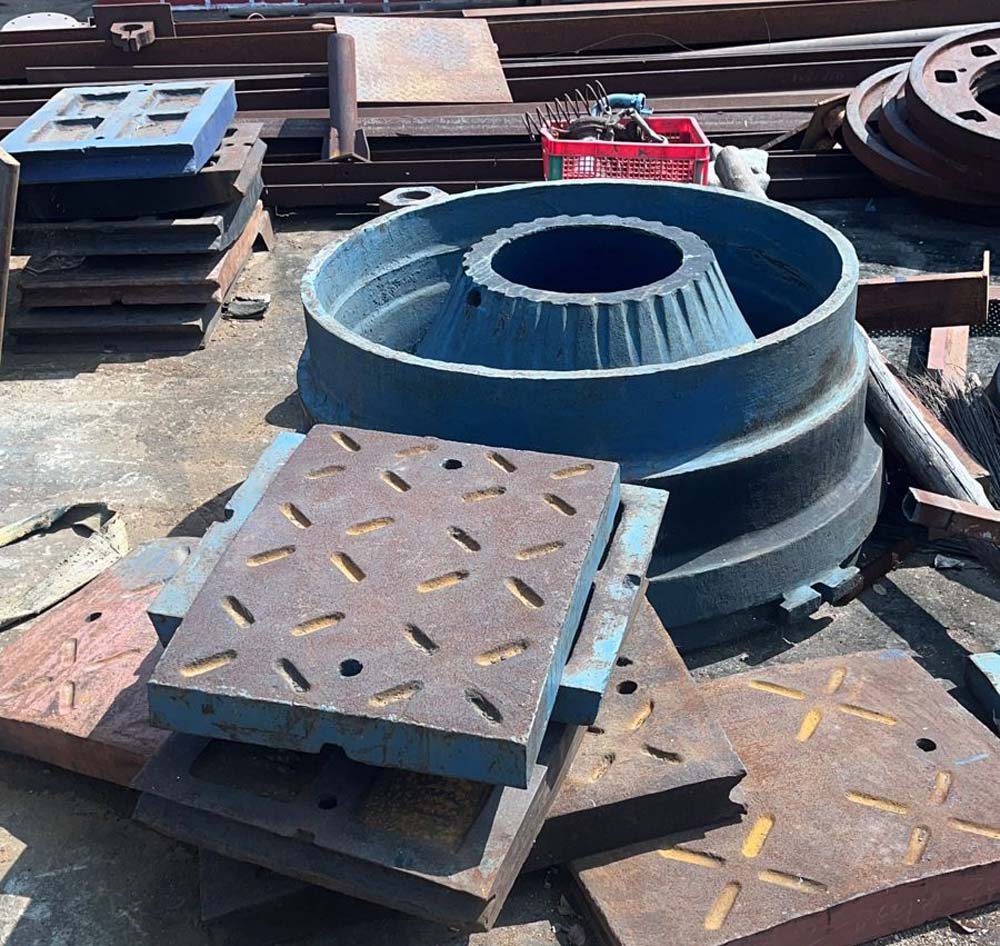

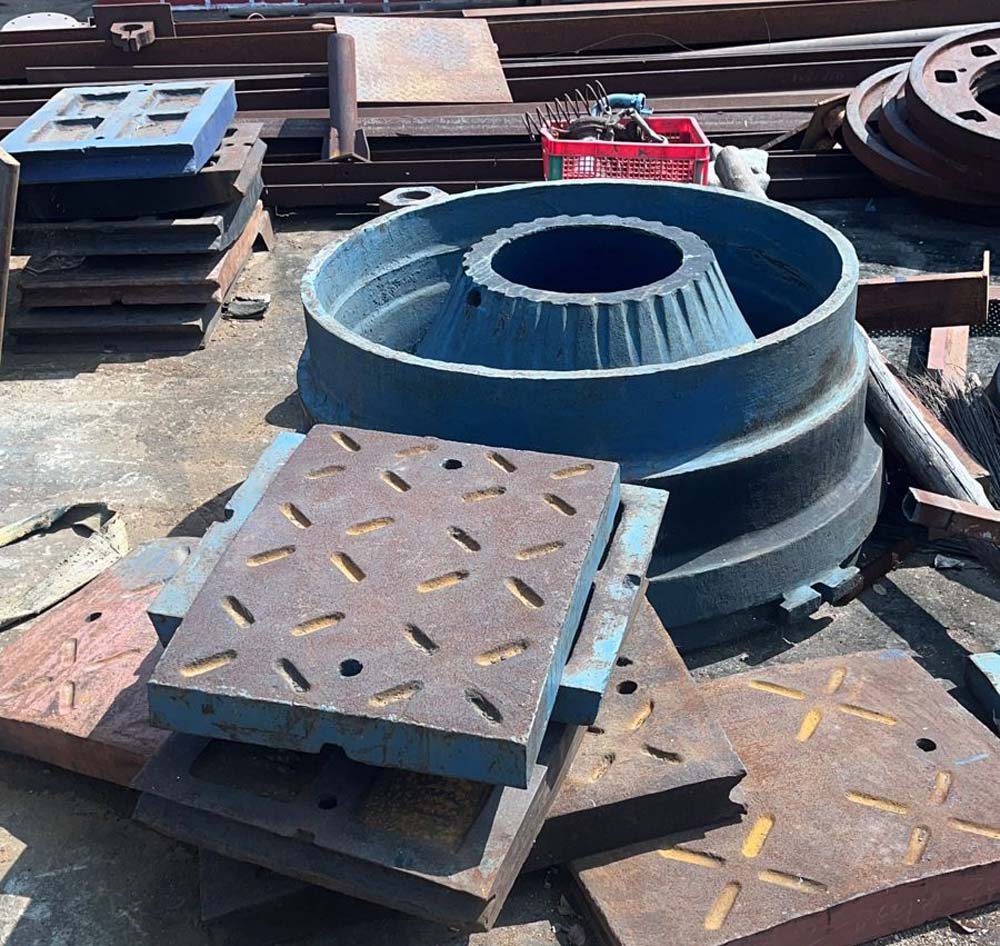

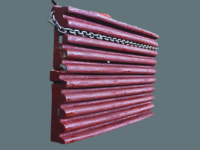

Manganese Steel Castings

Robust solutions for extreme wear resistance

- Exceptional toughness for heavy impact loads.

- High work-hardening capacity for wear resistance.

- Superior tensile strength.

Bhanu Special Castings Pvt. Ltd., a top metal casting company in Vijayawada, specializes in delivering high-quality metal casting services. We provide manganese steel castings, carbon steel castings, and stainless steel castings that exceed industry expectations.

Our expert team uses advanced technology to produce precision metal castings for industries like automotive, aerospace, and marine. With a commitment to quality and sustainability, we are among the top metal casting industries in the region.

Explore our premium metal castings in Vijayawad, including manganese steel castings, carbon steel castings, and stainless steel castings, designed for durability and performance.

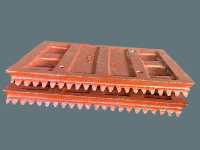

Robust solutions for extreme wear resistance

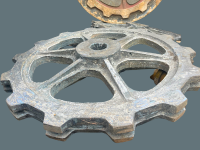

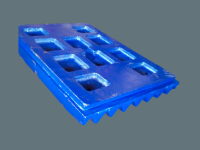

Versatile and cost-effective components

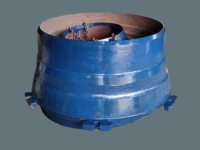

Durable and versatile for demanding applications

Strength and ductility for complex designs

Bhanu Special Castings Pvt. Ltd. operates a state-of-the-art facility in Vijayawada, producing high-quality alloy steel castings, manganese steel castings, stainless steel castings, and carbon steel castings adhering to national and international standards. Our advanced manufacturing facilities ensure precision and quality in every step of the process.

In-house facilities for metal casting services include:

Our fully equipped machine shop and foundry deliver exceptional dimensional accuracy, making us a trusted name in steel castings and alloy cast iron production across India.

Bhanu Special Castings Pvt. Ltd., a leading metal casting company in Vijayawada, ensures unmatched quality in metal castings. Certified with ISO 9001:2015, we implement stringent quality assurance from raw material to final product.

Our metal casting services include rigorous testing for manganese steel castings, carbon steel castings, and stainless steel castings, ensuring casting soundness, surface finish, and mechanical properties. Common tests include:

Our metal castings undergo in-process and final inspections by reputed third-party agencies like Lloyd’s, SGS, BVIS, and DNV, ensuring reliability for demanding environments.