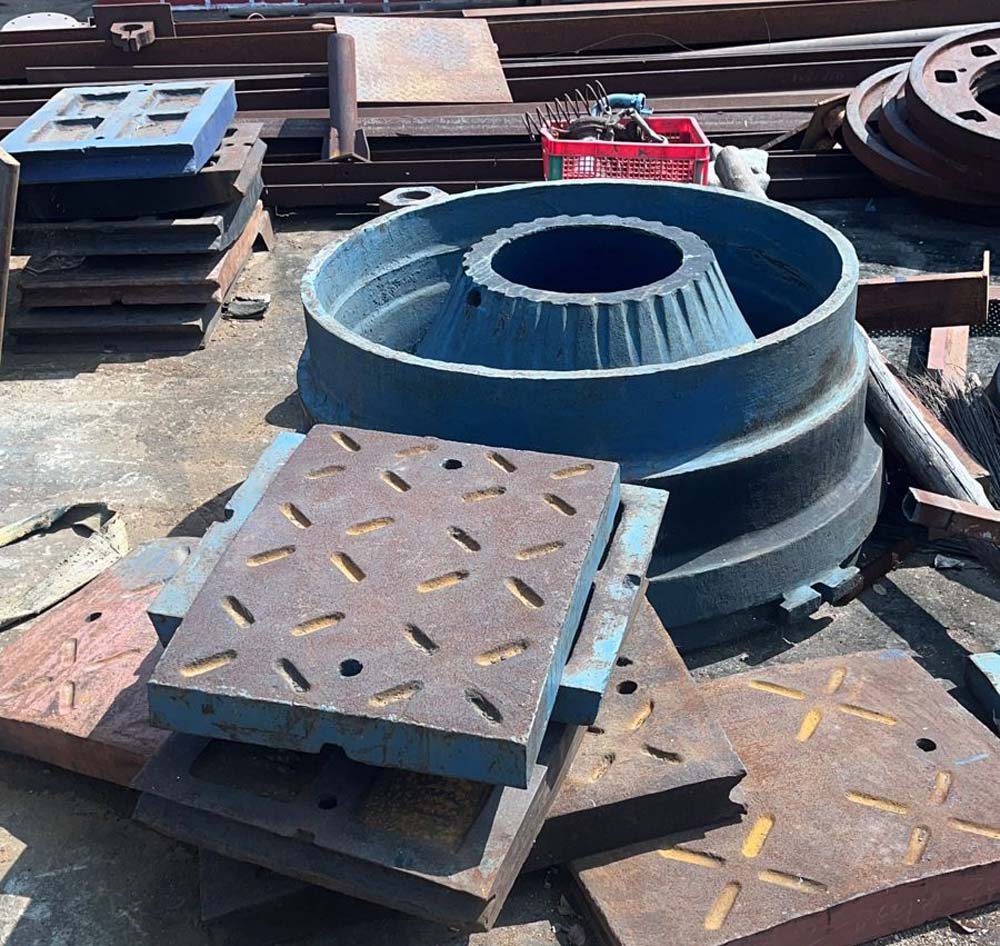

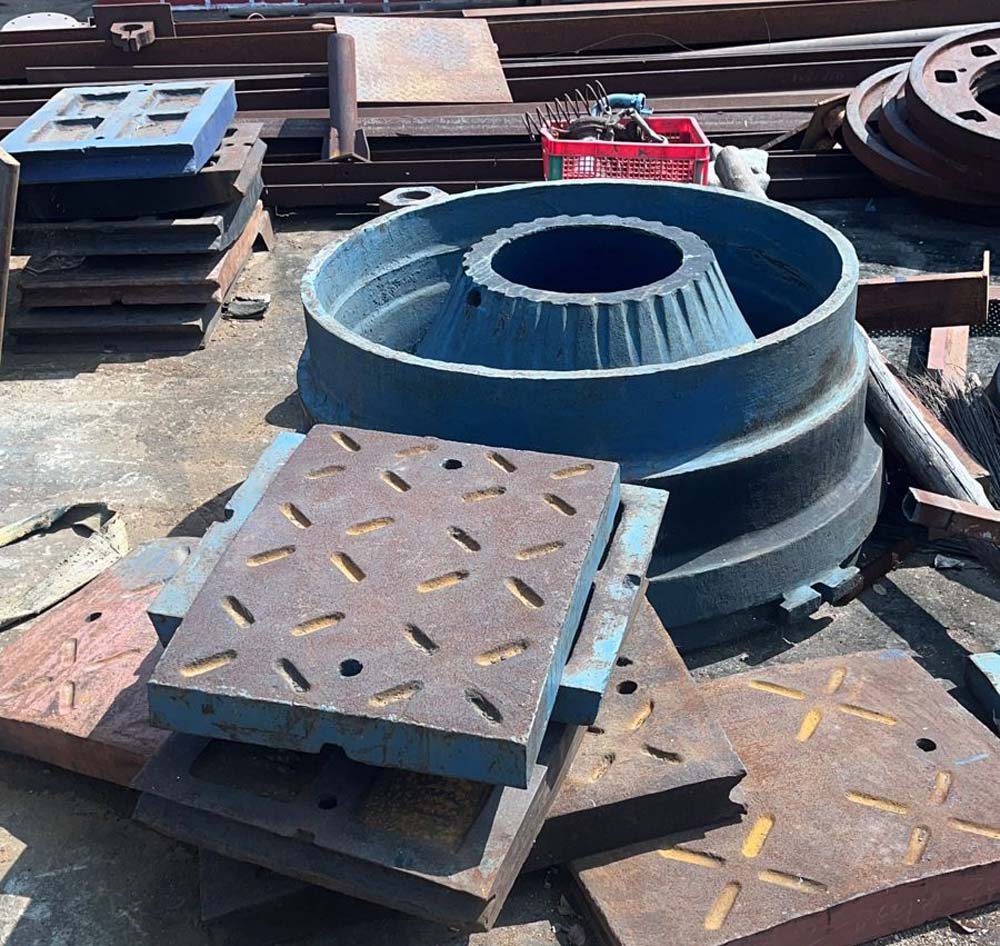

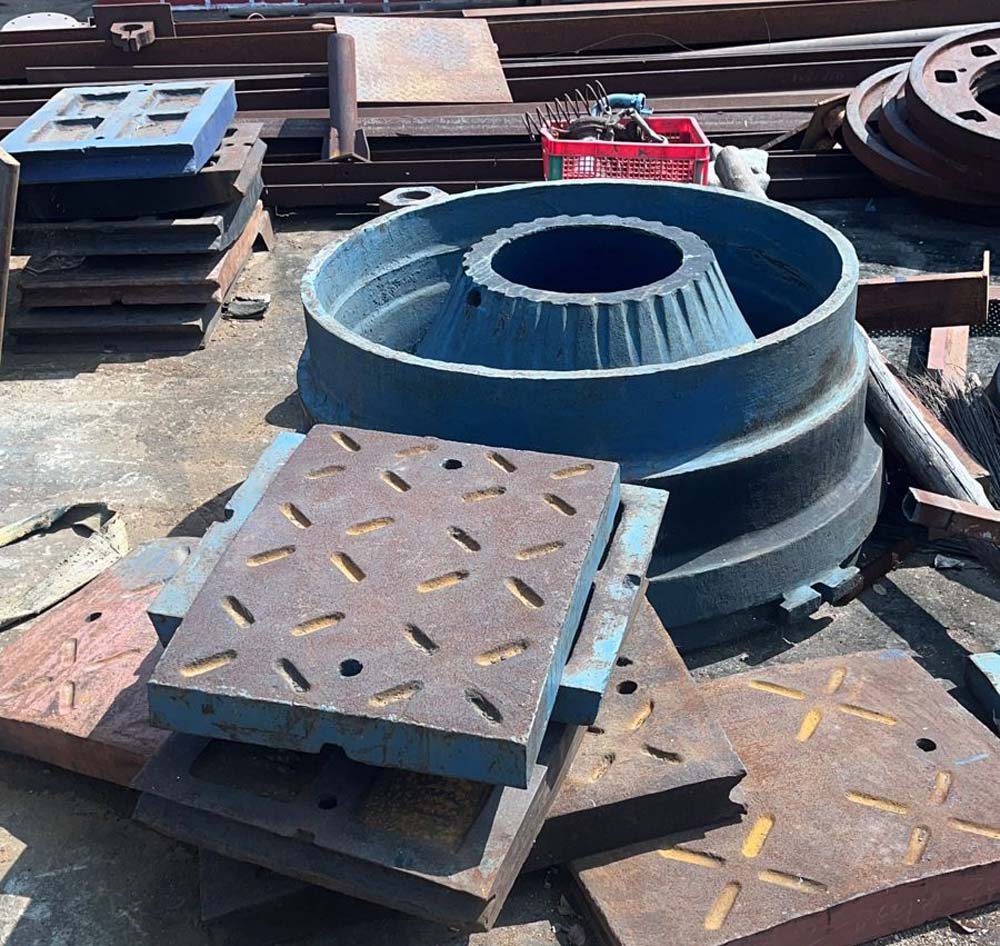

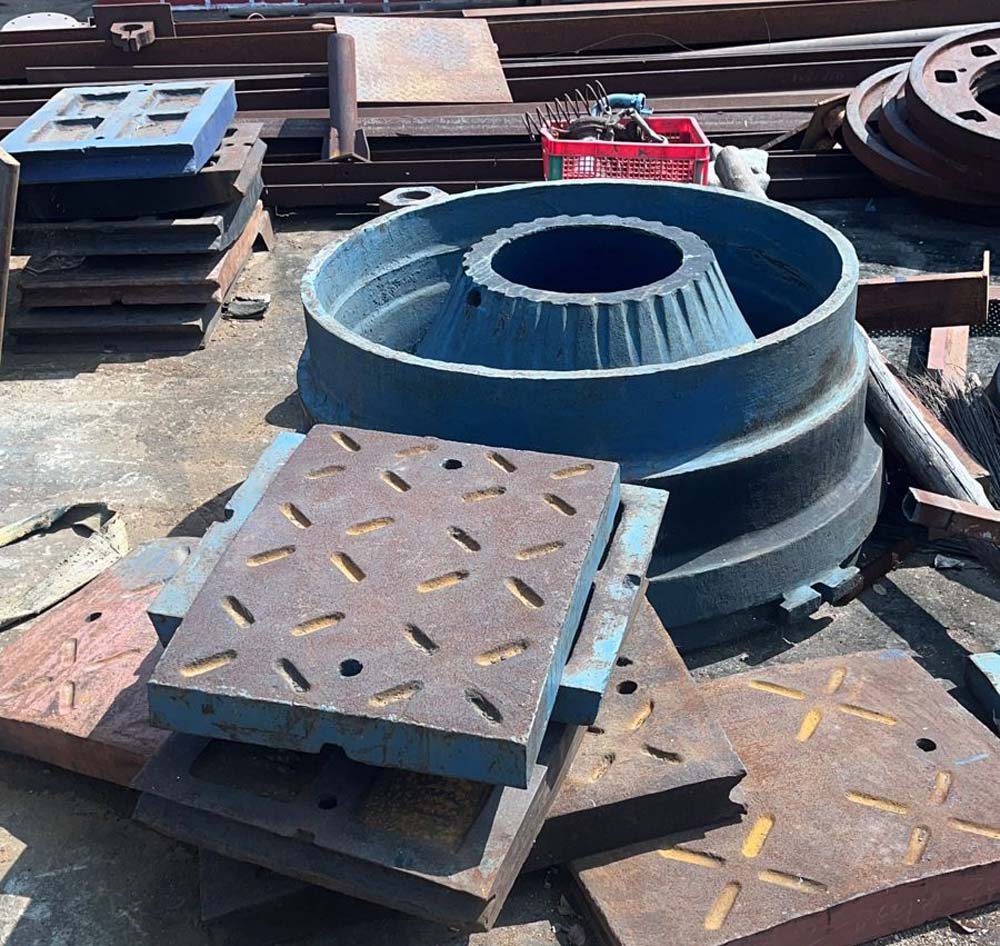

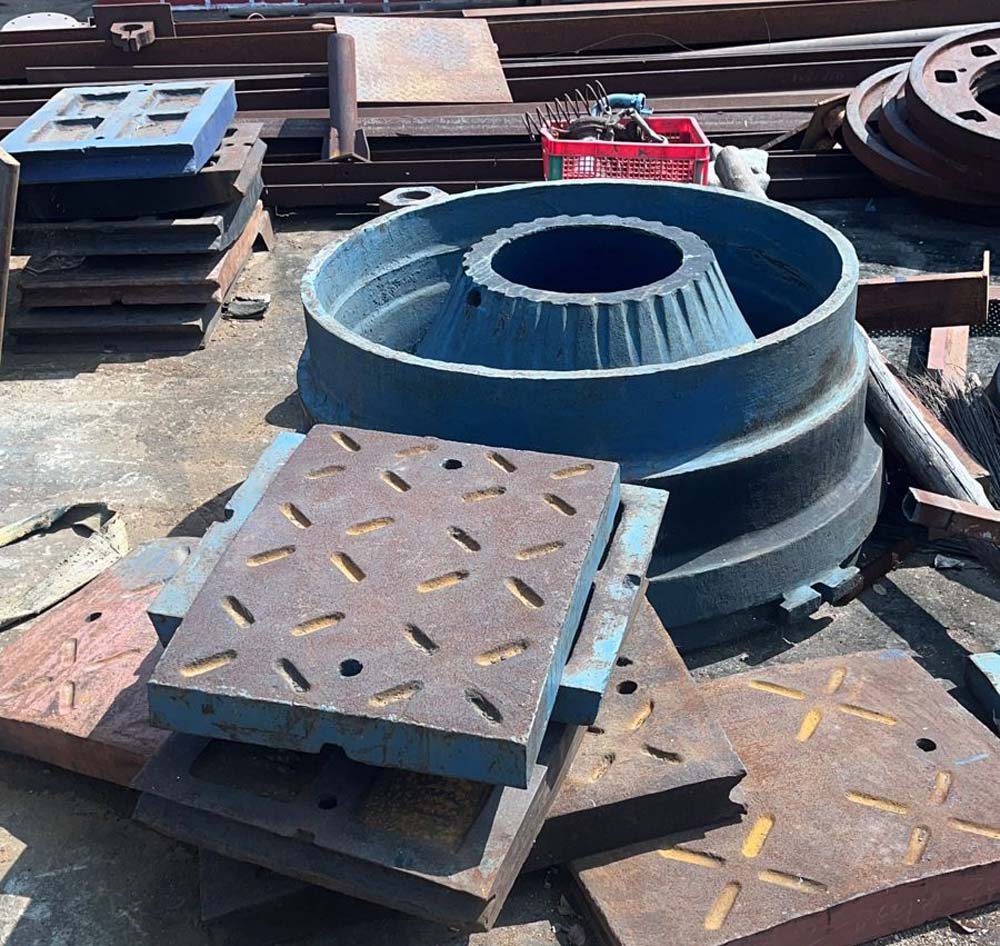

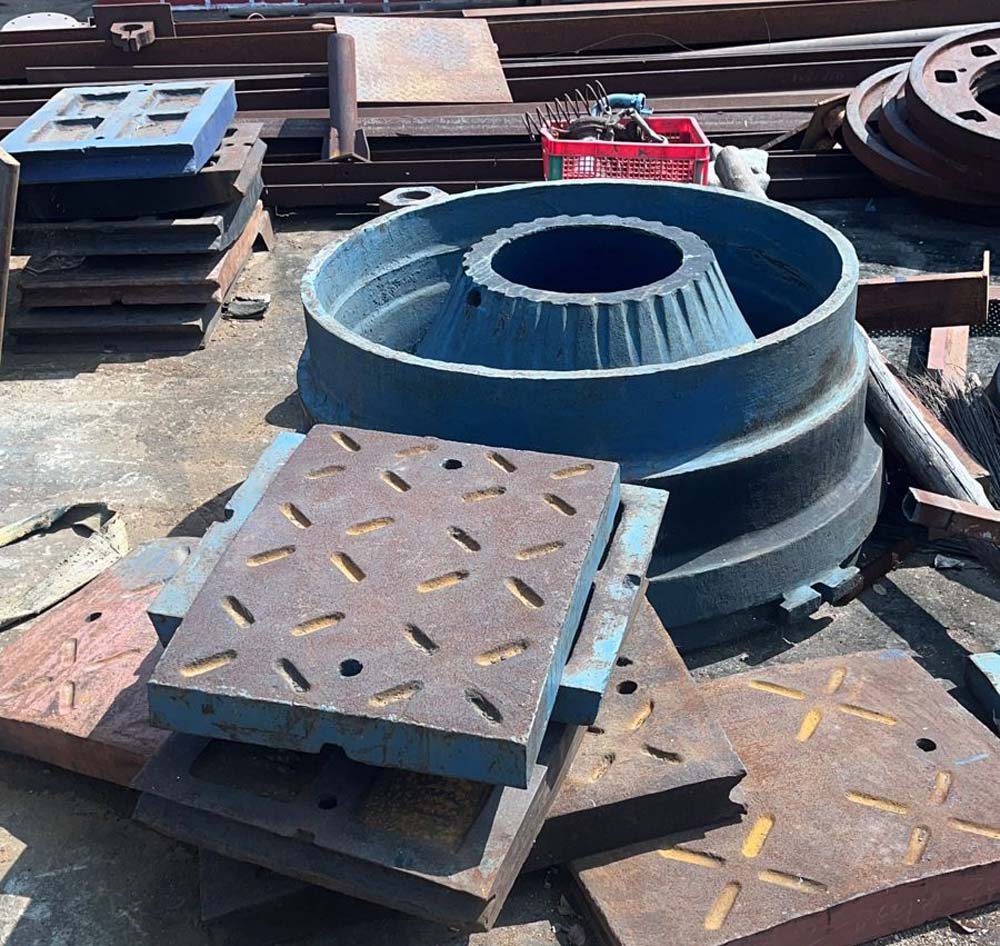

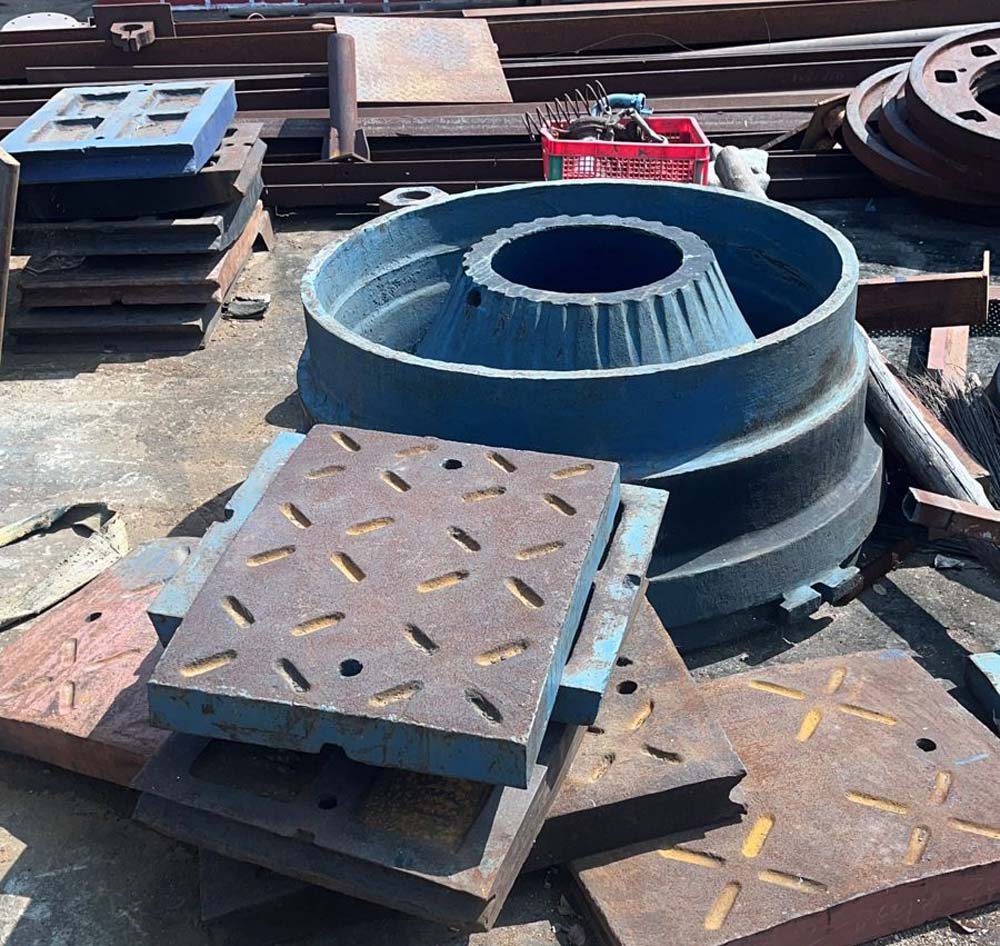

Manganese Steel Castings

Robust solutions for extreme wear resistance

- Exceptional toughness for heavy impact loads.

- High work-hardening capacity for wear resistance.

- Superior tensile strength.

A top metal casting company in Vijayawada, specializing in delivering high-quality metal casting services. We provide manganese steel castings, carbon steel castings, stainless steel castings, SG Iron castings, Cast Iron castings, Low Alloy steel castings, Ni Hard castings, Hi Chrome castings and Heat Resistant Steel castings that exceed industry expectations.

Our expert team uses advanced technology to produce precision metal castings for industries like automotive, aerospace, and marine. With a commitment to quality and sustainability, we are among the top metal casting industries in the region.

Your trusted partner for precision metal castings with uncompromising quality

Internationally recognized quality management system ensuring consistent excellence in all our metal casting services.

State-of-the-art 350kV induction furnaces and CNC machining centers for precision metal castings.

Skilled professionals with decades of experience in manganese steel castings, carbon steel, and stainless steel production.

Efficient production processes ensuring on-time delivery of custom metal castings in Vijayawada and across India.

Comprehensive quality checks including radiographic, ultrasonic, and chemical analysis through spectrometry.

Tailored alloy steel castings and components designed to meet specific industry requirements and applications.

Explore our premium metal castings in Vijayawada, including manganese steel castings, carbon steel castings, and stainless steel castings, designed for durability and performance.

Robust solutions for extreme wear resistance

Versatile and cost-effective components

Durable and versatile for demanding applications

Strength and ductility for complex designs

High strength with improved toughness

Corrosion-resistant and hygienic solutions

Extreme abrasion resistance solutions

Superior hardness for abrasive environments

Reliable performance at elevated temperatures

Our high-quality metal castings serve diverse industries across India, delivering reliability and performance where it matters most.

Durable manganese steel castings for crusher liners, jaw plates, cone liners, and impact hammers.

High-strength alloy steel castings for cement mill liners, grinding media, and kiln components.

Precision carbon steel castings and SG iron castings for engine and transmission components.

Corrosion-resistant stainless steel castings for marine pumps, valves, and propeller components.

Robust cast iron castings for excavator buckets, bulldozer blades, and loader components.

High-performance metal castings for turbine components, valve bodies, and pump casings.

Discover our comprehensive metal casting services, delivering precision and reliability for industrial needs.

Molding molten steel for intricate manganese steel castings with unmatched accuracy.

Enhancing carbon steel castings with robust properties through controlled heating.

Optimizing designs with advanced CAD for efficient stainless steel castings.

Rigorous NDT, chemical analysis, and mechanical testing by third-party agencies.

Ensuring alloy accuracy with spectrometry for metal castings.

Validating durability of metal castings with hardness and impact tests.

Detecting defects in metal castings using advanced non-destructive methods.

Delivering precision finishing for metal castings in Vijayawada.

Committed to international quality standards and industry best practices

Quality Management

Inspection Certified

Quality Verified

Approved Vendor

Certified Partner

From design to delivery - Excellence at every stage

Advanced 3D CAD design and engineering consultation to optimize your casting requirements

Precision pattern creation using CO2 sodium silicate process and green sand techniques

State-of-the-art 350kV induction furnaces ensuring optimal alloy composition and temperature control

Controlled heating processes to enhance mechanical properties and achieve desired hardness levels

Rigorous NDT, chemical analysis, and mechanical testing by third-party agencies

CNC machining and precision finishing for exact dimensional accuracy

Secure packaging and timely delivery to your location across India

Bhanu Special Castings Pvt. Ltd. operates a state-of-the-art facility in Vijayawada, producing high-quality alloy steel castings, manganese steel castings, stainless steel castings, and carbon steel castings adhering to national and international standards. Our advanced manufacturing facilities ensure precision and quality in every step of the process.

In-house facilities for metal casting services include:

Our fully equipped machine shop and foundry deliver exceptional dimensional accuracy, making us a trusted name in steel castings and alloy cast iron production across India.

Bhanu Special Castings Pvt. Ltd., a leading metal casting company in Vijayawada, ensures unmatched quality in metal castings. Certified with ISO 9001:2015, we implement stringent quality assurance from raw material to final product.

Our metal casting services include rigorous testing for manganese steel castings, carbon steel castings, and stainless steel castings, ensuring casting soundness, surface finish, and mechanical properties. Common tests include:

Our metal castings undergo in-process and final inspections by reputed third-party agencies like Lloyd’s, SGS, BVIS, and DNV, ensuring reliability for demanding environments.