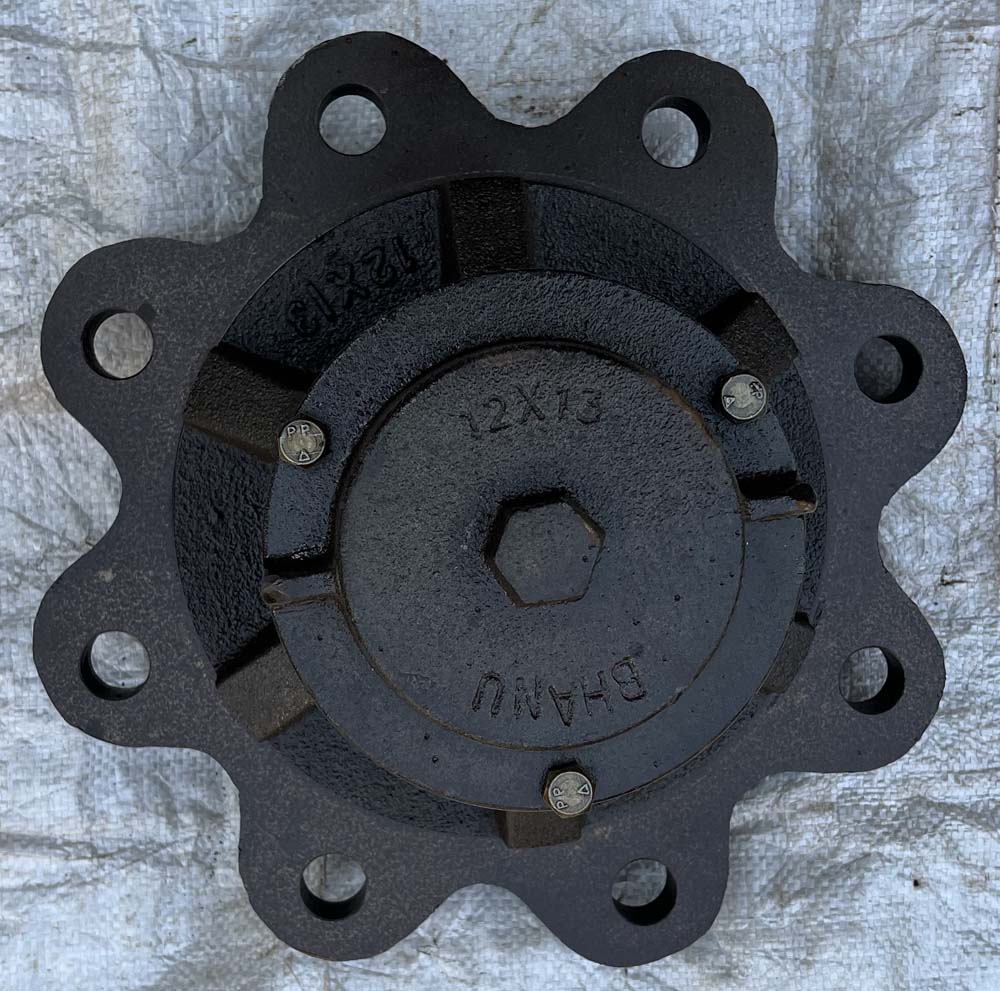

Bhanu Special Castings, Vijayawada – Hi Chrome Castings

Hi Chrome Castings

At Bhanu Special Castings Pvt. Ltd., a leading metal casting company in Vijayawada, we specialize in High Chrome steel manufacturing to produce premium high chrome castings engineered for extreme wear resistance and long-lasting performance. Our High Chrome casting services ensure reliability in the most demanding industrial environments.

High Chrome castings are known for their superior hardness, corrosion resistance, and durability, making them ideal for applications subjected to heavy abrasion and impact, such as grinding media, crusher parts, and slurry pump components . Our advanced manufacturing processes and stringent quality checks ensure products that meet and exceed industry standards.

Products

We offer a comprehensive range of high-performance High Chrome castings designed for superior abrasion resistance:

- Grinding Media for Mills

- Crusher Parts and Liners

- Slurry Pump Components

- Coal Pulverizer Rolls

- Boiler Tubes and Ash Handling Systems

- High Chrome Industrial Castings

Applications

Our High Chrome castings are widely used in industries where extreme wear, corrosion, and impact are encountered:

- Mining and Mineral Processing

- Cement Industry

- Power Generation

- Oil & Gas Industry

- Grinding Mills and Crushers

- Slurry and Abrasive Pump Components

High Chrome castings are engineered with high chromium content, often combined with carbon and other alloying elements, providing excellent hardness, abrasion resistance, and moderate corrosion resistance. These castings are essential for applications in mining, cement, power generation, and other industries requiring heavy-duty wear components.

Customization and Quality Assurance

We provide customized High Chrome castings tailored to your specific requirements, including unique alloy compositions, grades, and dimensions. Our experienced team in Vijayawada collaborates with clients to ensure castings meet precise operational and performance requirements.

Each casting undergoes thorough testing, including hardness, abrasion resistance, and dimensional accuracy checks, to meet international standards. Our modern facilities in Vijayawada ensure consistent quality and timely delivery of High Chrome castings .

Grades and Applications of High Chrome Castings

Our High Chrome castings are produced in multiple grades to cater to diverse industrial needs. Common grades include ASTM A532, AS 2027 , EN 12513, EN 100Cr6 (1.3505), EN 1.4034 (X46Cr13), EN 1.4112 (X90CrMoV18), EN 1.4016 (X6Cr17) , and EN 1.4568 (X2CrNiMo18-14-3).

These castings are widely adopted in industries where extreme wear, corrosion, and impact occur. Key applications include:

- Mining & Mineral Processing: Grinding media, crusher parts, slurry pump components.

- Power Generation: Coal pulverizer rolls, boiler tubes, ash handling systems.

- Cement Industry: Grinding media and wear liners for cement mills.

- Oil & Gas Industry: Mud pump liners, drilling tools, and valve components.

- Industrial Pumps: Abrasive fluid handling components.

- Grinding Equipment: Mill liners, media, and plates.

- High Wear Machinery Parts: Crusher and pulverizer components.

- Custom Castings: Special grades and dimensions as per client requirements.

| Grade | Properties | Common Applications |

|---|---|---|

| ASTM A532 / EN 12513 | High hardness, excellent abrasion resistance, moderate corrosion resistance | Grinding media, crusher liners, slurry pump components |

| EN 100Cr6 (1.3505) / EN 1.4034 (X46Cr13) | High-carbon, chromium alloy, excellent wear resistance, good corrosion resistance | Coal pulverizer rolls, boiler tubes, valve parts, high-wear industrial components |

Product Gallery