Bhanu Special Castings, Vijayawada – Low Alloy Steel Castings

Low Alloy Steel Castings

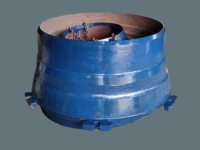

At Bhanu Special Castings Pvt. Ltd., a leading metal casting company in Vijayawada, we specialize in Low Alloy Steel manufacturing to produce premium low-alloy steel castings engineered for high strength, toughness, and durability. Our Low Alloy Steel casting services deliver reliable performance for critical industrial applications.

Low Alloy Steel castings are designed by adding controlled amounts of alloying elements (typically less than 5-8%) to carbon steel, enhancing properties such as hardness, wear resistance, corrosion resistance, and overall mechanical strength. These castings are ideal for components subjected to heavy loads and demanding environments.

Products

We offer a comprehensive range of low-alloy steel castings designed for enhanced strength and wear resistance:

- Stone Crusher Spares: Jaw holders, toggle plates

- Thermal & Power Plant: Valve housings, rollers

- Mining & Earthmoving: Excavator adaptors

- Heavy Engineering: Gear castings, mould bases

- Sugar & Agriculture: Crown pinions, harvester gears

- Automobile & Sponge Iron: Axle hubs, bearing housings

Applications

Our Low Alloy Steel castings are widely used across industries requiring high strength, and wear resistance:

- Mineral Processing Equipment

- Thermal and Power Generation Plants

- Mining & Earthmoving Machinery

- Cement, Sugar, and Agriculture Industries

- Heavy Engineering & Automobile Components

- Sponge Iron & Steel Plant Applications

Low Alloy Steel castings are available in multiple grades such as IS 1030, EN 8, EN 18, EN 19, EN 24, EN 36, EN 353, IS 2707, IS 2708, IS 2644, 24CrMo4, Cr2 Mo4 WCA, WCB, WCC, LCB, WC1 . These castings provide enhanced mechanical properties for critical components like gears, shafts, structural supports, crusher spares, and industrial machinery parts.

Customization and Quality Assurance

We provide customized Low Alloy Steel castings tailored to specific industrial requirements. Our team in Vijayawada ensures the production of precise components, adjusting alloy compositions, grades, and dimensions according to client specifications.

Every casting undergoes rigorous testing for hardness, toughness, dimensional accuracy, and mechanical performance. Our advanced facilities guarantee consistent quality and timely delivery of Low Alloy Steel components .

Grades and Applications of Low Alloy Steel Castings

Our Low Alloy Steel castings are produced in multiple grades to meet a variety of industrial needs. Common grades include IS 1030, EN 8, EN 18, EN 19, EN 24, EN 36, EN 353, IS 2707, IS 2708, IS 2644, 24CrMo4, Cr2Mo4, WCA, WCB, WCC, LCB, WC1 .

These castings are ideal for applications requiring high strength, toughness, and reliability. Typical use areas include:

- Stone Crusher Industry: Stationary jaw holders, swing jaw holders, toggle plates, flywheel castings

- Thermal & Steel Plants: Valve housings, bull ring segments, shrink-fit rollers

- Mining & Earthmoving: Excavator adaptors, bearing housings, crusher body spares

- Cement & Heavy Engineering: White metal bearing bodies, gear castings, mould bases, die blocks

- Sugar & Agriculture: Crown pinions, harvester driving gears, trailer hubs, trash plates

- Automotive & Sponge Iron: Axle hubs, spider hub castings, bearing housings

| Grade | Properties | Common Applications |

|---|---|---|

| EN 8 / EN 18 / EN 19 | High strength, good toughness, moderate wear resistance | Gears, shafts, structural components, machinery parts |

| EN 24 / EN 36 / IS 1030 | High tensile strength, excellent toughness, suitable for heavy-duty applications | Crusher spares, industrial rollers, flywheels, bearing housings |

Product Gallery